Color Removal

Textile plants, particularly those involved in finishing processes, are major water consumers and the source of considerable pollution. Pulping and bleaching processes release colored compounds into the effluent stream. Most of the color comes from removing lignin in the bleaching operation, particularly in the caustic extraction stage. The color exists in a range of physical forms, from suspensions to true solutions. Conventional treatment processes remove some color. Primary and (biological) secondary treatments are not usually more effective than this in removing soluble color.

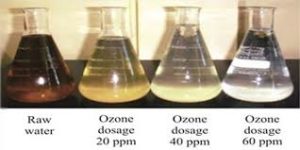

Ozone emerges as the most universal solution offering satisfactory efficiency. It produces an effluent with no color, low COD, and suitable for discharge into the environment or return to the process.

Ozone is effective in removing the color from all dyes used in textile processing. The amount of ozone can vary depending on a number of factors: how much color was removed in the biological process, the type of dye used, where ozone is applied in the process, etc. Knowing the proper amount of ozone required to meet the color removal objective for the receiving water body is critical to the economics of the ozone system. In general it is not easy to predict the amount of ozone required, so in virtually all cases where specific previous experience is not available, pilot testing is employed.

The best results concerning color removal are achieved if the wastewater has been previously treated in order to lower the values of the other characteristics so that the ozone oxidizing effect is “consumed” only or at least at a maximum proportion in color removal.